Automatic hot water boiler ROJEK TKA 80

Automatic hot water boiler ROJEK TKA 80 allows to burn brown coal with grain size 4 - 25 mm or wood pellets with diameter 6 - 8 mm, quality white, but also with bark mixture. Thanks to the fuel tank, electronic control and the burner with screw feeder, the boiler can work in automatic mode for several days. The boiler is supplied with a 800 litre storage hopper placed on the right or left side. The ST 480 zPID control unit is standard with the boiler. This type of boiler meets the highest emission class 3 for brown coal and emission class 4 for pellet. This boiler meets EKODESIGN. This type of boiler has a controllable output of 20 - 80 kW. A set of grates for manual mode can be purchased for the boiler and the boiler can be used for manual heating - wood, wood briquettes - in the temporary period.

Product code: 1082003

Technical parameters

| Nominal power - brown coal | 20 - 74 kW |

| Nominal power - pellets | 23 - 80 kW |

| Efficiency - pellets/ brown coal | 90% / 88% |

| Boiler class according to EN 303-5 pellets / brown coal | 4/3 |

| Energy efficiency class pellets / brown coal | A+ / C |

| Seasonal energy efficiency pellets / brown coal | 81% / 79% |

Boiler emissions according to Regulation (EU) No 2015/1189 - Brown coal | EKODESIGN |

| Flue gas temperature range | 77 - 127 °C |

| Specified chimney draft | 28 - 30 Pa |

| Dimensions (w x h x d) | 1605x1772x1552 mm |

| Chimney height | 1669 mm |

| Chimney diam. (chimney extension diam.) | 210 (219) mm |

| Volume of standard fuel tank (right standard / left standard) | 800 l |

| Volume of fuel tank larger than standard | 1200 l |

| Boiler water volume | 300 l |

| Boiler connections - inlet and outlet water diameter | G 2" |

| Electrical connection voltage | 230 V / 50 Hz |

| Maximum electrical input | 110 W |

| Boiler weight | 1240 kg |

Description of the boiler

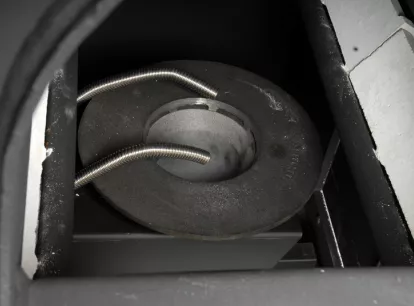

The automatic hot water boiler TKA 80 allows you to automatically burn brown coal with a grain size of 4 - 25 mm or wood pellets with a diameter of 6 - 10 mm, quality white, but also with a mixture of bark. A retort burner is installed in the boiler, which is designed on the principle of lower fuel supply to the combustion section and the combustion itself resembles burning in a forge. From the feed chamber, the fuel is fed by a feeder into the cast-iron retort tube. Here it is pushed upwards onto a circular grate. The retort is placed in a stirrer into which air is blown by a fan. The burnt fuel - ash and slag - falls over the edges of the grate into the ash tray.

The ROJEK TKA 80 boiler is supplied with a 800 l fuel storage on the right or left side.

The boiler is equipped with a modulation unit ST 480 zPID.

This unit controls:

-

This unit controls:

- the burner fan (continuously controls the fan speed)

- the fuel feeder (controls the dosage according to the required output)

- the central heating circulating water pump (DHW)

- the hot water pump

- the boiler circuit pump

- the circulation pump

The controller includes a module for controlling a four-way or three-way mixing vent in the base. Furthermore, the ST 480 zPID controller can work with an equithermal sensor, with other four-way or three-way vents, with a room thermostat, with a GSM module, with a Wifi module and with an Ethernet module (via the Internet).

A set of grates for manual mode can be purchased for the boiler and the boiler can be used for manual heating - wood, wood briquettes - in the temporary period.

These hot water boilers meet the requirements of EN 303 - 5, Boiler Class 4 for pellet boilers and Boiler Class 3 for coal boilers.

Katalog kotlů

(Katalog-TT-Rojek-final.pdf)

Katalog kotlů

(Katalog-TT-Rojek-final.pdf)

Do you need us now?

Do you need us now?