Hot water boiler KTP 80

The ROJEK KTP 80 hot water boiler for manual feeding is designed for burning brown coal size "Kostka" (emission class 4). For this fuel, it meets the EKODESIGN. This type of boiler is very popular with our customers because it is easy to operate and clean. The boiler does not need electricity to operate, it is fanless and without electronics. The boiler can be connected to both the solitary and compulsory circulation with a pump. This type of boiler is not sensitive to fuel quality.

Product code: 1081004

Technical parameters

| Rated power | 80 kW |

| Boiler width | 748 mm |

| Boiler depth | 1263 mm |

| Boiler height | 1405.5 mm |

| Grate depth | 1060 mm |

| Height of flue pipe | 1302.5 mm |

| Flue diameter (diameter of the extension on the boiler) | 220 (219) mm |

| Water inlet height | 252 mm |

| Building depth | 1535 mm |

| Diameter of water inlet and outlet | G 2" |

| Max. diameter/length of logs | 23 / 100 cm |

| Volume of combustion chamber | 200 l |

| Boiler weight | 875 kg |

| Brown coal efficiency | 89,3 % |

| Boiler class according to EN 303-5 brown coal | 4 |

| Boiler emissions according to Commission Regulation (EU) No 2015/1189 | EKODESIGN |

| Energy efficiency class brown coal | C |

| Seasonal energy efficiency brown coal | 80 % |

| Boiler hydraulic loss | 0.4 mbar |

| Dimensions of the filling opening - semicircle width x height | 395 / 295 mm |

| Volume of water in the boiler body | 300 l |

| Maximum operating water overpressure | 2 bar |

| Minimum operating water pressure | 0,5 bar |

| Test water pressure | 4 bar |

| Maximum operating temperature | 90 °C |

| Prescribed chimney draft brown coal | 25 Pa - 32 Pa |

| Flue gas temperature at rated output brown coal | 220 °C - 300 °C |

| Flue gas volume flow - nominal output brown coal | 320 m3 /h |

| Recommended volume of the accumulation tank | 3500 l |

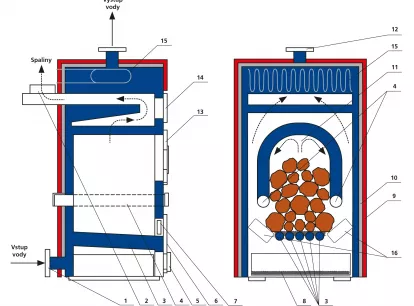

Description of the boiler

The hot water boiler KTP 80 for manual feeding is designed for burning lump wood and brown coal Kostka (40 - 100 mm), calorific value 17 - 20 MJ/kg. For this fuel the boiler meets Class 4 according to EN 303 - 5. Other alternative fuels are short piece wood, briquettes, fresh sawdust, wet wood chips and other wet biomass.

This is made possible by the original design of the boiler, with dual (two-stage) combustion of the fuel, approximately 80% gasification and approximately 20% conventional combustion. Thanks to the combination of both types of combustion, the fuel is perfectly utilized and burnt out. Both primary and secondary air supply can be easily controlled, thus achieving optimum combustion and long fuel burn-out times.

The boiler is constructed of a double steel structure (inner plates 5 mm thick, outer 4 mm) filled with water. The water is also in a solid grate made of heat pipes. This design ensures maximum transfer of heat energy and at the same time prolongs the life of the boiler.

Advantages of KTP boilers:

- 6-year warranty on the tightness of the boiler body

- ability to burn a wide range of fuels

- it is also possible to burn wet fuel or biomass

- thanks to the double combustion, the mixture is perfectly burnt through, thus suppressing the formation of harmful emissions and condensates

- the boiler is designed for a chimney draft of 30 - 40 Pa, therefore it does not need an electric exhaust fan to operate

- the boilers are equipped with an aftercooling loop (overheating protection) and allow operation both on the heating water circulation alone and on forced circulation

- thetemperature of the return water can drop to 55º C, this is made possible by the fact that the return water is fed back into the boiler directly into the tubular grate of the fireplace

- flue gas temperature 220 - 300 °C

- the boiler can be connected without a storage tank if operated at rated output

KTP boilers meet emission Class 4 and can be used after 2022.

Katalog kotlů

(Katalog-TT-Rojek-final.pdf)

Katalog kotlů

(Katalog-TT-Rojek-final.pdf)

Do you need us now?

Do you need us now?