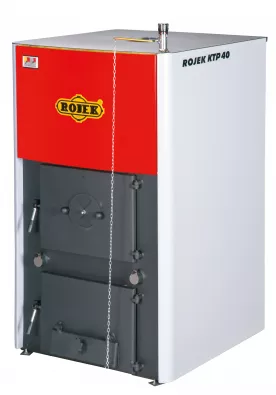

Pyrolytic boiler ROJEK PK 40

Pyrolytic boiler ROJEK PK 40 for manual loading is designed to burn dry wood 530 mm long and brown coal (grain size 20-40 mm) or coal cube (grain size 40-100 mm). The advantage of the boiler is a large combustion chamber of 130 litres and thus a long burn-out time. Another advantage of the boiler is the upper loading of the combustion chamber and easy cleaning of the heat exchanger by means of a control lever. The boiler is controlled by ST 86 zPID electronics and an exhaust fan is located at the rear of the boiler. This modern, environmentally friendly boiler complies with emission class 5 for fuel wood and emission class 4 for fuel brown coal according to the Norm EN 303-5. For both fuels it meets the conditions of EKODESIGN. We recommend this boiler to customers looking for a heating source for both wood and coal.

Product code: 1043400

Technical parameters

| Nominal power - wood | 40 kW |

| Nominal power - brown coal | 40 kW |

| Efficiency - wood | 89 % |

| Efficiency - brown coal | 86 % |

| Boiler width including control lever / without control lever | 916 / 784 mm |

| Boiler depth | 1145 mm |

| Boiler height | 1232 mm |

| Chimney height | 574 mm |

| Chimney diameter (diameter of the boiler extension) | 160 (159) mm |

| Flue gas temperature at rated output - wood | 220 - 250 °C |

| Flue gas temperature at rated output - brown coal | 170 - 210 °C |

| Electrical input (230V/50Hz) | 76 W |

| Volume of the loading (firing) chamber | 180 l |

| Boiler water volume | 130 l |

| Water inlet height | 449 mm |

| Installation depth | 1408 mm |

| Diameter of water inlet and outlet | G 2" |

| Boiler class according to EN 303-5 - wood | 5 |

| Boiler class according to EN 303-5 - brown coal | 4 |

| Energy efficiency class - wood | A+ |

| Energy efficiency class - brown coal | C |

| Seasonal energy efficiency - wood | 77,5 % |

| Seasonal energy efficiency - brown coal | 77 % |

| Boiler emissions according to Commission Regulation (EU) No 2015/1189 | EKODESIGN |

| Max. diameter / length of wood | 250 / 530 mm |

| Boiler weight | 615 kg |

| Max. water overpressure | 2 bar |

| Min. operation temperature | 63 °C |

| Specified chimney draught - wood | 18 Pa |

| Specified chimney draught - brown coal | 18 Pa |

| Optimum storage volume | 2200 l |

| Wood consumption in nominal power | 10,9 kg/h. |

| Consumption of brown coal in nominal power | 9 kg/h. |

Boiler description

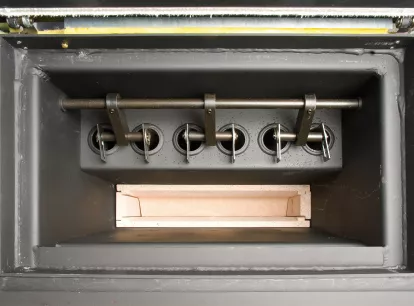

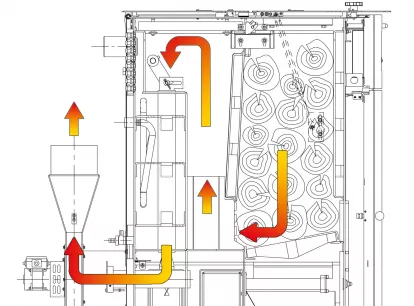

Pyrolytic boiler ROJEK PK 40 for manual feeding is designed to burn firewood - piece wood 530 mm long, fuel moisture up to 20%, heating value 14 - 18 MJ/kg, or brown coal (grain size 20 - 40 mm), or coal cube ( grain size 40 - 100 mm), fuel moisture max. 15%, heating value 14-20 MJ/kg. The boiler is certified according to Norm EN 303-5 for fuel wood in emission Class 5 and for fuel brown coal in emission Class 4. The main advantage of ROJEK PK boilers is the top filling of the loading chamber, which allows to fully use the chamber volume, both for lump wood and for smaller size fuels or for brown coal. Thanks to the large loading chamber, the burn-out time is long. The boilers are controlled by an electronic control unit that controls the combustion in the boiler and the exhaust fan. Cleaning the heat exchanger is also very easy with the help of a control lever and a cleaning bottom door that is accessible from both outside sides. The boiler body is welded from quality steel. All surfaces in contact with the flue gases are made of sheet metal of thickness. 5 mm. The other surfaces are made of 4 mm thick sheet metal. The weight of the boiler, which is 615 kg, will convince you of the honestly made boiler weldment. For trouble-free operation of the boiler, connection with a storage tank is necessary. The boilers of this series are designed for economical and environmentally friendly heating.

Advantages of pyrolytic boilers ROJEK PK 40:

- Upper loading - very easy and quick - by opening the upper loading door

- Smokeless loading in the boiler room - Exhaust fan

- Long burn-out time - large combustion chamber volume (180 l)

- Fuel selection - wood or brown coal

- Max. wood length 530 mm

- Easy cleaning of the tubular exchanger with the help of a cleaning lever and cleaning door

- Cooling loop is included in the boiler - overheating protection

- The boilers are controlled by an electronic control unit which controls: the exhaust fan, boiler water temperature - starting the pump and switching off the fan, UT water temperature control, manual or automatic mode (several different variants of automatic mode), burn-out time, manual operation during flooding, adjustable fan speed, flue gas sensor, boiler and controller protection, audible alarm.

- Quick start of the boilers is ensured by a larger area of the boiler body and heat exchanger, which are evenly filled with water, which gives the assumption of a longer service life of the boiler body

- High efficiency up to 89%

- Ecological combustion - the boilers comply with Class 5 and 4 according to the Norm EN 303 - 5 and EKODESIGN

- 3 years warranty on the boiler body, extended warranty of 5 years when connected with a storage tank

- Connection of the accumulation tank is necessary for efficient boiler operation

The controller is equipped with zPID program.

In addition to the standard sensors, the controller is also equipped with a flue gas sensor. The control of this type consists in controlling the flue gas temperature and boiler water temperature. Based on these values, the control changes the fan speed to maintain the set boiler water temperature. The flue gas sensor of the control unit saves up to 13% of fuel and the outlet water temperature is very stable, which prolongs the life of the boiler. The boiler can be supplemented with a master control (EU-i-1, EU-i-2 PLUS, EU-i-3 PLUS), which is from the same manufacturer as the electronics on the boiler.

ROJEK PK series manual feed boilers are recommended to be operated with ROJEK accumulation tanks with properly selected accumulation water volume, where it is recommended to consider 40 - 80 l of accumulation water per 1 kW of installed power. The minimum recommended storage tank volume for the ROJEK PK 40 boiler is 1600 l.

Katalog kotlů

(Katalog-TT-Rojek-final.pdf)

Katalog kotlů

(Katalog-TT-Rojek-final.pdf)

Do you need us now?

Do you need us now?